Coal & Biomass Gasification

i. Gasification

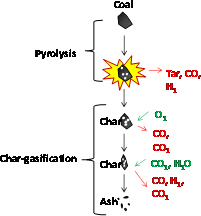

- Gasification is defined as the process of reacting a carbon-rich feedstock (coal, petroleum coke, biomass, waste, etc.) with steam and oxygen to form a synthesis gas containing H2 and CO.

- Syngas can be utilized at IGCC (Integrated Gasification Combined Cycle) or IGFC (Integrated Gasification Fuel Cell Combined Cycle) for power generation.

ii. Experimental research on coal & biomass gasification

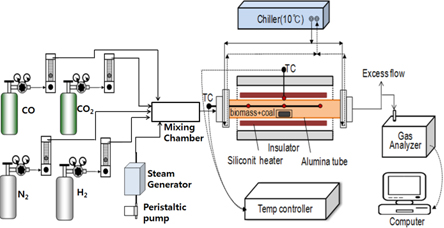

- Experimental study on co-gasification by using tube furnace and gas analyzer.

- Kinetic parameters (activation energy and pre-exponential factor) of gasification can be acquired from experimental data.

- Empirical model of gasification can be derived from experimental result.

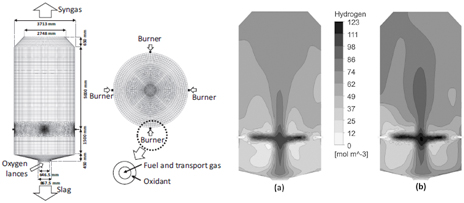

iii. Computational fluid dynamics (CFD) modeling of gasification

- Gasifier can be simulated with computational fluid dynamics (CFD) software.

- The effect of coal/biomass ratio, particle size and various operating parameter on gasification can be determined by computational fluid dynamics study.

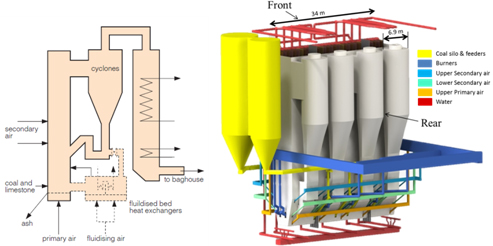

Circulating fluidized bed technology

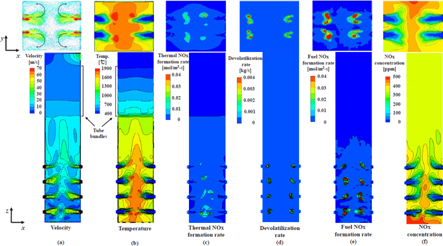

i. Numerical simulation on fluidized bed combustor

- Circulating fluidized bed technology is an ideal technology to be used for large scale power generation with a broad variety of biomass fuels

- The benefits of CFB technology is the superior fuel flexibility, inherently low emissions and high availability

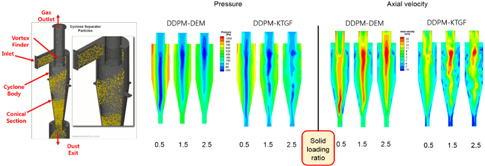

ii. Numerical simulation on cyclone

- Cyclone separator is a particle separation device that uses centrifugal force generated from the spinning airflow to separate particles suspended in the air stream.

- Easily remove the particles flowing with air and does not require frequent maintenance and replacement

Numerical approach for power generation facilities

i. Numerical simulation on industrial combustor

- Numerical simulation on industrial combustor (Pulverized coal or Heavy fuel oil fired).

- Spatial distributions of the flow, species concentration, and temperature can be predicted from the numerical simulation with low cost.

- Numerical simulation can be used for combustion diagnosis and modification (lower emission, higher efficiency).

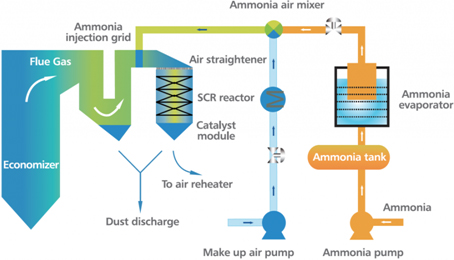

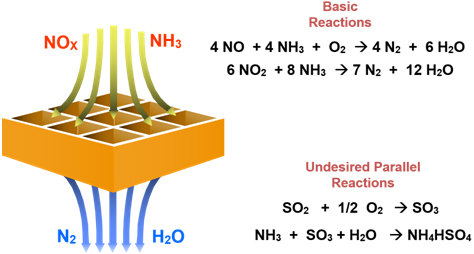

ii. Numerical studies on SCR (selective catalytic reduction)

- Selective catalytic reduction (SCR) is a means of converting nitrogen oxides, also referred to as NOxwith the aid of a catalyst into diatomic nitrogen (N2) , and water (H2O)

iii. Numerical studies on corrosion reduction in waste incinerator

- Chlorine, which is rich in municipal wastes, forms during combustion and results in high temperature corrosion on the heat exchanger tube surface.

- Sulfate solution is injected upstream of the heat exchanger to feed sulfur and convert into .

- (NH4)2SO4(aq)→2NH3(g)+H2O(g)+SO3(g)

- 2KCl(g)+SO3 (g)+H2O(g)→K2SO4(c)+2HCl(g)