Bio-aerosol sampling/detection

ⅰ. Rapid monitoring of infectious bioaerosols

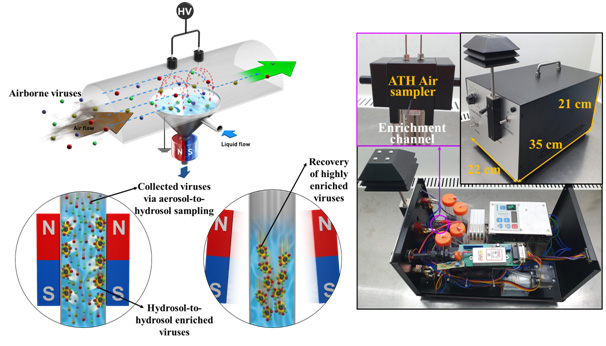

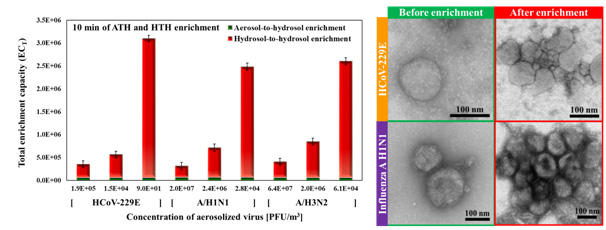

- Airborne infectious viruses (Coronavirus and influenza viruses) entering the electrostatic air sampler are charged by the air ions and collected on the continuously flowing liquid (aerosol-to-hydrosol (ATH) sampling).

- The ATH-collected viruses were simultaneously delivered to a fluidicchannel for hydrosol-to-hydrosol (HTH) enrichment.

- The injected viruses adsorbed onto the concanavalin A (ConA) coated magnetic particles (CMPs) installed on the inner wall of the channel for enrichment.

- After the enrichment, fresh liquid wasinjected into the channel to flush out the enriched viruses for analysis

ⅱ. Rapid monitoring of infectious bioaerosols

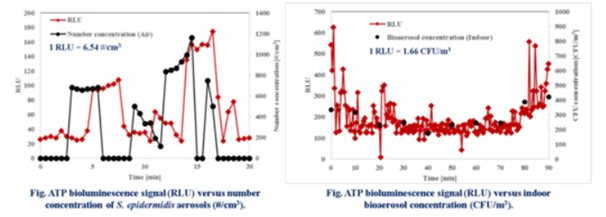

- Bioaerosols were charged by the air ions and sampled in a flowing liquid containing both a cell lysis buffer and adenosine triphosphate (ATP) bioluminescence reagents.

- While the liquid was delivered to the bioluminescence detector, sampled bioaerosols were dissolved by the cell lysis buffer and ATP was extracted

- The ATP was reacted with the ATP bioluminescence reagents, causing light to be emitted.

- When the concentration of bacteria in the aerosols was varied, theATP bioluminescence signal in relative light units (RLUs) closely tracked the concentration in particles per unit air volume (#/cm3), as measured by an aerodynamic particle sizer (APS).

- In the field test with indoor bioaerosols, it was found that the variation of the bioluminescence signal closely followed the variation in CFU concentration and 1 RLU corresponded to 1.66 CFU/m3 of indoor bioaerosols.

Aerosol measurement technology

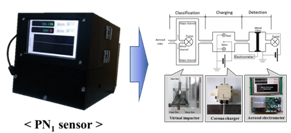

- PN1 (Particle Number less than 1µm) sensor was designed and fabricated for real-time measurement of indoor air quality.

- The sensor comprised a particle-classification unit(virtual impactor), a particle-charging unit (corona charger), and a particle-detection unit (aerosol electrometer).

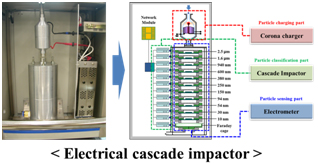

- For measurement of number based size distribution of PM(Particulate Matter) 5, an electrical cascade impactor (ECI) is designed and fabricated.

- The ECI is composed of particle charging part (corona charger), particle classification part (cascade impactor), and particle sensing part (Electrometer).

- The 11-stage electrical cascade impactor was applied to measure the size distribution of PM2.5 in real-time.

Non-thermal plasma for environmental applications

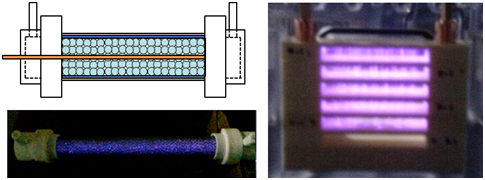

i. Dielectric Barrier Discharge

- Dielectric barrier discharge (DBD): non-thermal plasma discharge generated by high AC voltage applied between two electrodes with dielectric barrier.

- DBD has higher energy density than corona discharge.

- DBD is widely used in various gas purification processes (VOC removal, NOx/SOx removal, PM removal, O3 generation)

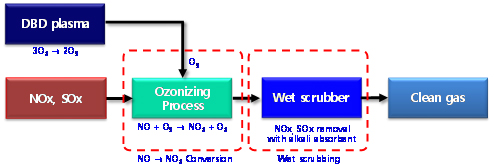

ii. NOx/SOx removal

- Water solubility of gas is an important factor for high scrubbing efficiency.

- NOx consists of NO (not soluble to water) and NO2 (soluble to water).

- In general, 95% of NOx is emitted as NO.

→ Portion of NO2 should be increased for NOx scrubbing. - DBD ozonizing methodwas proposed to increase portion of NO2. (NO + O3→ NO2 + O2)

- With this process, simultaneous removal of NOx and SO2 is possible in wet scrubber.

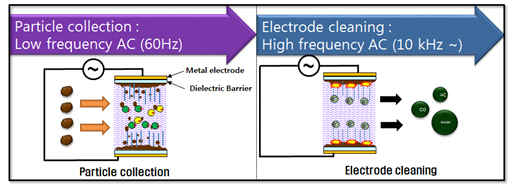

iii. Self-cleaning electrostatic precipitator

- DBD reactor can be used as electrostatic precipitator.

- At the low frequency (60Hz) AC power operation, DBD plasma can collect particles by particle charging and electrostatic force.

- Collected particles can be removed from electrode by applying high frequency AC power to Dielectric barrier discharge.

- At high frequency, collected particles are decomposed to gas species (CO2, CxHy, ...) by highly energetic ions and electrons in the plasma.